Cobots vs COVID-19

Solara Automation can assist you in addressing your factory labor challenges. Furthermore, we specialize in helping our customers overcome the challenges of deploying and integrating new factory automation.

Mandatory factory shutdowns and restrictions on movement have, consequently, brought economic activity in entire regions to a standstill. Furthermore, manufacturers must now choose between the unappealing prospect of closing facilities until restrictions are lifted or the daunting challenge of swiftly implementing automation to sustain current operations.

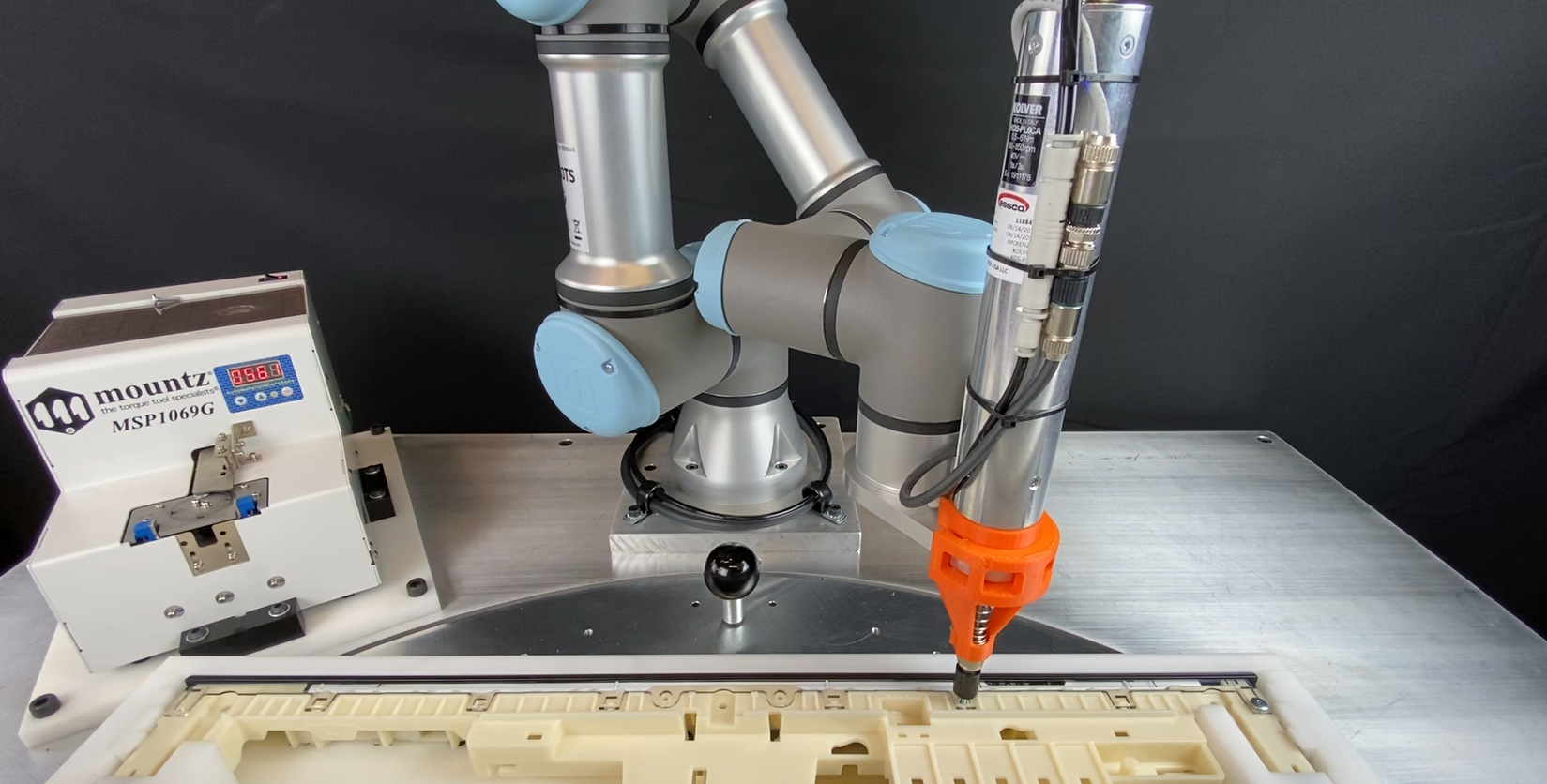

Today, with manufacturing in dire need of flexible solutions, it makes sense to consider cobot-based quality control and inspection systems. Furthermore, Solara Automation can seamlessly integrate them into your existing production lines. What sets these UR cobots apart is their unique ability to achieve results in fast-moving quality control environments. They can swiftly transition from pick and place and handling roles to inspection tasks. This ease of reconfiguration allows cobots to inspect new parts with agility. This not only positions cobots as the ideal technology for future-proofing inspection processes but also guarantees business continuity in challenging times.

This operational flexibility also applies to human-robot collaboration. If you need to enforce social distancing requirements at your manufacturing facility, consider introducing cobots to your quality control lines. Implementing cobots will enhance the accuracy of your QC operations, allowing workers to be reassigned to more demanding tasks. Solara Automation can guide you through the process of implementing these new solutions at your facility. With our proven track record in integrating this new type of robotic cell, inform us how we can assist you with yours.

Contact Solara Automation based in beautiful Morrisville, North Carolina today.

Please view all of our application videos and follow us here.