Valve Stem Seal Trimmer and Inspection Machine

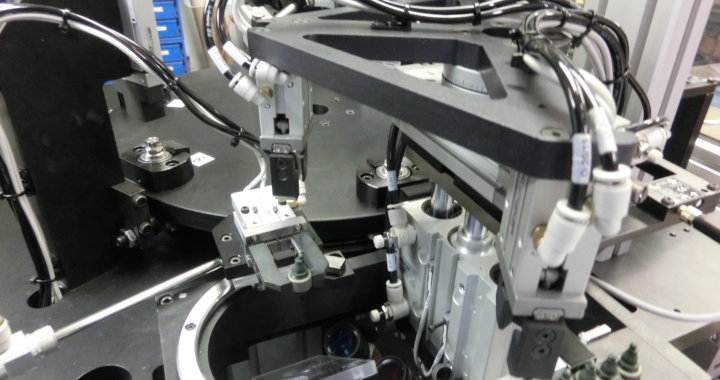

Valve Stem Seal Trimmer and Vision Inspection System

Application: Process, Assembly, and Vision Inspection System

Industry: Automotive

Customer product is a valve stem seal used in engines. The customer needed to trim rubber, assemble spring, and inspect parts for defects.

AAE North America designed a system to feed parts, load them on an indexing dial, cut the excess rubber, and assemble the spring. The parts were rotated at various stations for cutting and inspection of all sides. A 7-camera vision inspection system was required to inspect for spring integrity, part height, trim depth, non-fill, over-fill, pinholes, and chipped edges. Additionally, each part was verified to have the correct letter code molded into the rubber. Reject parts were sorted into different bins by type of defect.

Features of Valve Stem Seal Trimmer and Vision Inspection System

- 20 parts / minute

- Vibratory bowl feeders for parts & springs

- Pneumatic pick and place loading and unloading

- 6 station cam-driven dial with rotary nests

- Servo trim blade height adjustment

- 7 PPT M-series cameras running on 2 vision processors

- Detects total of 10 defects on parts

- Custom vision user interface displays inspection results and gives user control of system parameters

- Allen Bradley PLC controls

Videos:

F:\ARS\ARS1\Video\MOV10B.MOD –riding on dial