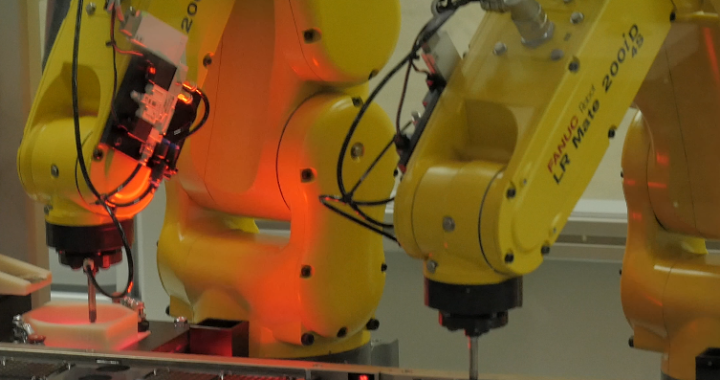

Tray Loader Robot Cell

Tray Loading Robotic Cell

Application: Material Handling

Industry: Electronic components

Our customer selected AAE North America to significantly enhance the production of a minuscule gold part (measuring down to 0.020” x 0.020”) essential in the electronics industry. The task involved bulk feeding these tiny components and packaging them in trays of varying sizes.

The system needed to be highly adaptable, allowing for effortless incorporation of new parts and swift transitions between different production configurations.

AAE North America responded by designing and constructing a robotic cell featuring two robots assigned the same task. Each robot operates independently, ensuring uninterrupted production even if one encounters issues. To achieve efficiency, both robots are engaged in the same task, and they can function autonomously if one robot faces downtime.

The system utilizes interchangeable vacuum nozzles, each as small as 0.005”, mounted on spring-loaded tools for precise part picking.

To adapt to a broad spectrum of product sizes, the system employed two flexible vibratory part feeders, allocating one for each robot. The robots meticulously control the timing of the feed and spread cycles, ensuring precise coordination. Overhead cameras and the integrated feeder backlight play a crucial role in accurately locating the parts, facilitating smooth and precise production operations.

To achieve the necessary precision in fitting small parts into trays, the system ensures seamless operations.

Parts, once picked from the feeder, swiftly pass over an upward-facing camera for immediate high-magnification imaging. Position data is instantaneously relayed to the robot, allowing real-time adjustments before placement in the tray.

For prolonged unattended operation, a tray feeder unloads, feeds, and stacks 20 metal pallets with 8 part trays each. Robots use precision techniques, aided by overhead cameras and integrated tray feeder backlights, for accurate tray recognition.

Features of Tray Loader Robot Cell

- 70 parts / minute

- 2 Fanuc LR Mate robots

- Custom vacuum nozzles on spring-loaded end-of-arm tools

- Flexible vibratory parts feeders with integrated backlights

- Indexing, stacking tray feeder

- 8 Cameras: Fanuc iRVision

- PC controls