Robotic Welding Cell for Cover Assembly

Robotic Welding Cell for Cover Assembly

Application: Material Handling, Laser Welding - Robotic Welding Cell for Cover Assembly

Industry: Electronic components

Customer product is small (0.09” x 0.011”) gold part used in electronics industry. Needed to bulk feed components, assemble components together, laser weld them, and package in both trays and stacks.

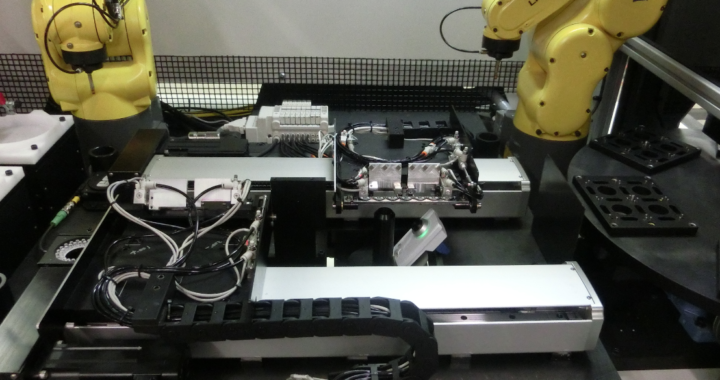

Solara constructed a three-robot cell, utilizing two flexible vibratory part feeders to accommodate various product sizes. The load robots control the timing of feed/spread cycles and locate parts through overhead cameras and the integrated feeder backlight.

The two loading robots work in tandem to maintain a high production rate. They alternate their actions with precise timing and anti-collision algorithms, each loading a component from the feeders into the assembly nests.

To meet the demanding tolerances, the process involves each part undergoing an initial pick from the feeder. Subsequently, they pass over an upward-facing camera, which captures a high-magnification image of the part held by the robot tool. The position data derived from this image is transmitted to the robot, enabling real-time corrections before the part is placed in the nest.

The nests tilt, shake, and clamp the parts to align and hold them in position for the index to the laser welder. To weld any desired pattern, servo-driven slides move each of the nests as well as the welder head. After each part is indexed above the weld head, a third robot unloads the parts into either trays or stacks, depending on the part recipe. An indexing dial presents the finished parts to an operator outside the guard frame.

Features of Robotic Welding Cell for Cover Assembly

- 30 parts / minute

- 3 Fanuc LR Mate robots

- Custom vacuum nozzles on spring-loaded end-of-arm tools

- Flexible vibratory parts feeders with integrated backlights

- Dual nests and welder head on dual servo-controlled slides

- Indexing outfeed dial

- 5 Cameras: Fanuc iRVision

- Allen Bradley PLC controls

Videos:

F:\Coining\COI2\CIMG2615.MOV