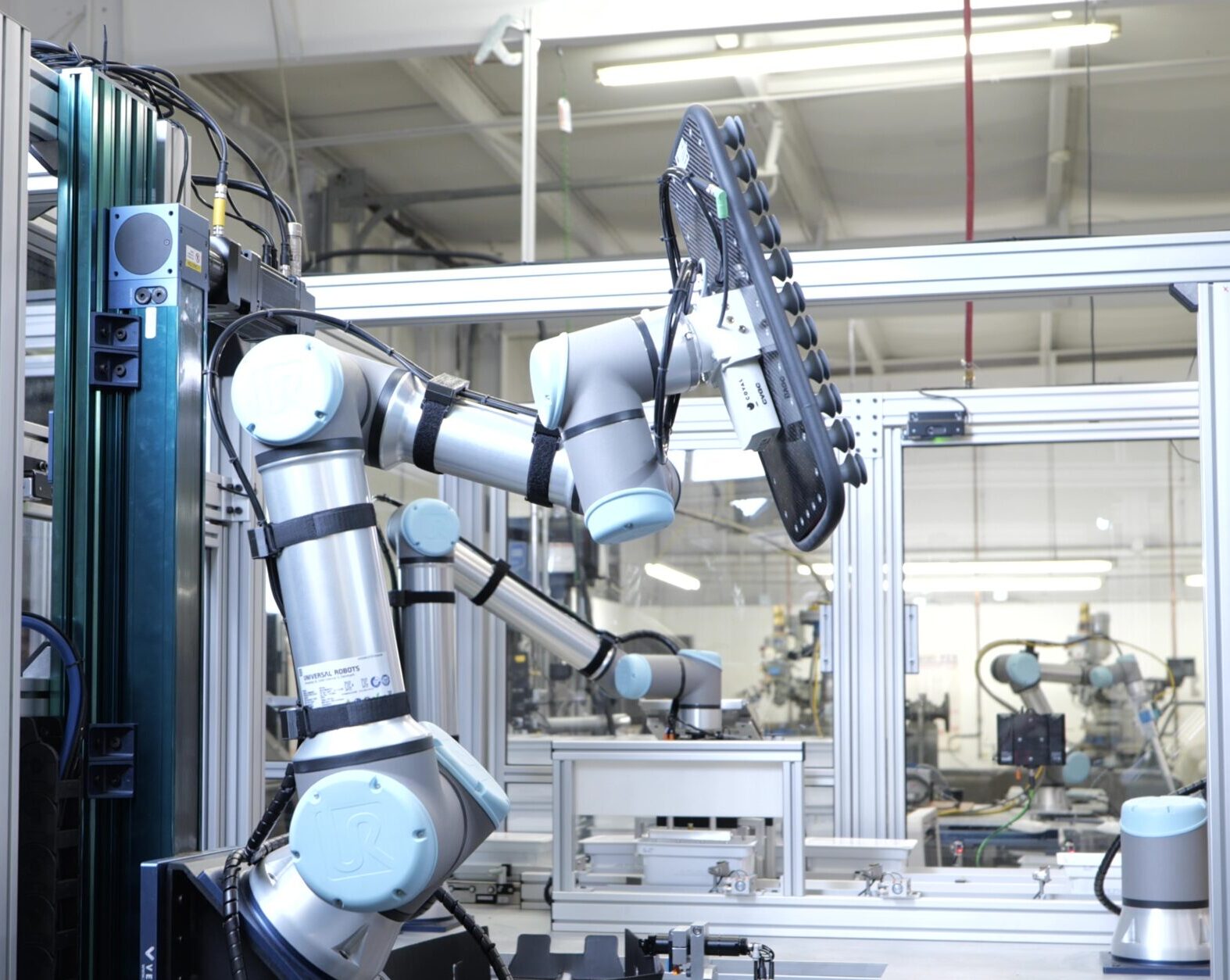

Universal Robot Depalletizing and Machine Tending System for Pharma Manufacturing

Meeting the highest quality and performance standards in pharmaceutical manufacturing, this fully automated custom machine tending cell feeds a high-speed syringe packaging machine running 24/7. The system also inspects to confirm syringe counts and accumulates packing materials for recycling.

Upon receiving customer cartons on pallets into the robotic cell, a Universal Robot, equipped with an additional vertical 7th axis, intricately selects cartons, opens them, extracts syringe tubs, and responsibly flattens the cartons.

At the same time, the efficiency of the system receives a notable boost as two Universal Robots work in collaboration to load syringe-filled tubs into the packaging machine, guaranteeing a smooth and streamlined process.

After completing the loading phase, the system smoothly transitions into a quality control stage. It retrieves the empty tubs and conducts meticulous inspections on each one to confirm the successful loading of all syringes. Any tubs discovered to be incomplete are then selectively separated from those with the intended syringe count. Furthermore, the system actively segregates plastic components for recycling, demonstrating a commitment to sustainable and eco-friendly practices.

The Depalletizing and Machine Tending System represents another customer success story by the talented design and build team at AAE North America.