Assembly / Process Machinery Case Studies Machine Vision Robotics

BaerWebDesign

Automotive, Fixed Automation, Machine Tending, Material Handling, Measurement, Pick & Place, Quality

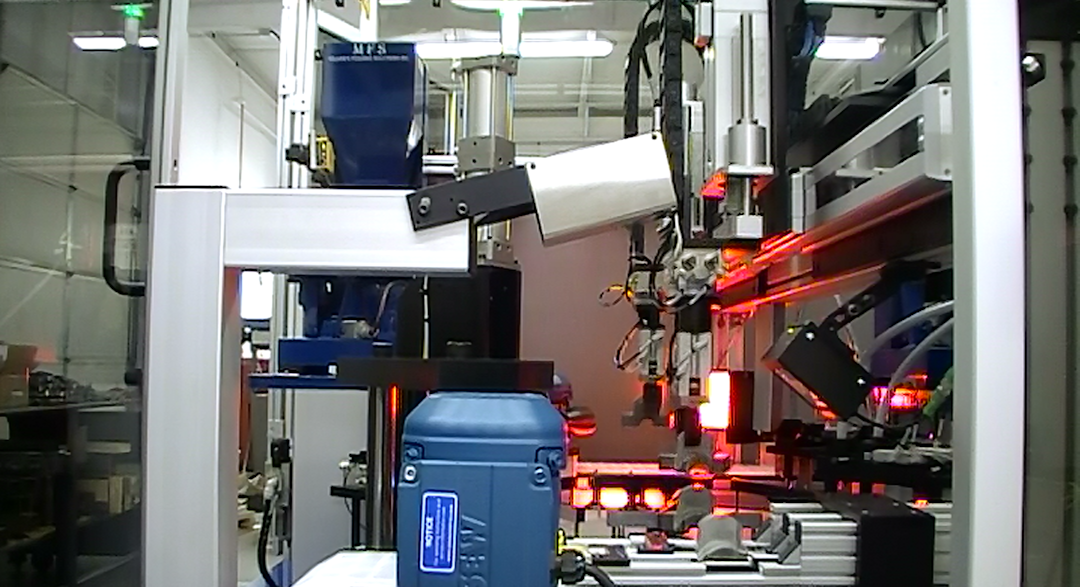

Dowel Assembly and Inspection Systems

Application: Assembly and Inspection System

Industry: Automotive

Solara Automation was approached by a client in the engine parts industry, with the task of assembling dowels and pins into sintered metal parts. In addition to assembly, the client also required inspection of the finished product for defects and verification of the correct depth of dowel insertion. To meet these requirements, Solara engineered and built two automated machines capable of assembling and inspecting five different parts.

A vision system was an essential component in inspecting the parts for missing material, dents, and black specks. Additionally, it was used to verify the proper depth of dowel insertion, and to orient the pick-and-place station for correct part orientation. One of the main challenges faced by Solara was the variability in the parts, particularly with regards to their coloring. Therefore, Solara needed to incorporate dynamic vision tools that could adapt to different batches of parts that were colored slightly differently, while also ensuring adequate lighting for inspection purposes.

Features of Dowel Assembly and Inspection System

- 16 parts / minute

- The Vision System adapts its vision tool thresholds on-the-go to effectively handle diverse batch parts

- 6 station cam-driven dial assembly system

- Dual IAI servo multi-axis pick-and-place system for part loading/unloading

- 4 PPT M-series cameras, one vision processor

- Flat dome light creates contrast for defects

- The vision system possesses the capability to adjust its tool thresholds in a dynamic manner to cater to various batch parts with ease.

- Measures dowel insertion depth using dual cameras with telecentric lenses

- Allen Bradley HMI/PLC controls