Collaborative Robots, Getting Them on Your Floor Takes More

It is easy to order a new collaborative robot these days. Many automation suppliers offer many different flavors of cobot for all types of applications. Online ordering by direct users has jumped dramatically.

So, getting the cobot to your facility was fairly easy, along with unpacking and setup. Now you are ready to start programming. This is where the rubber meets the road.

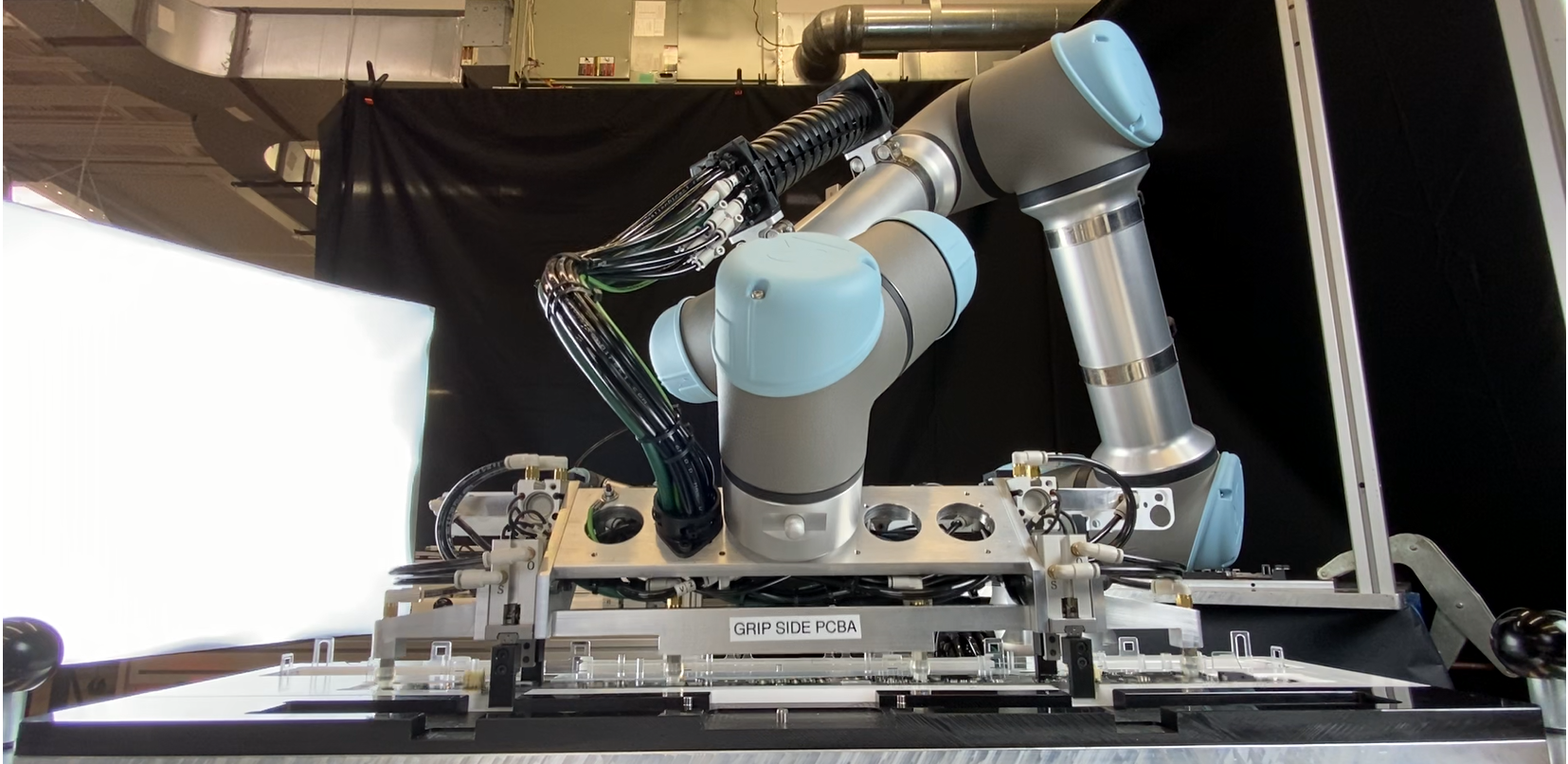

Collaborative robot manufacturers market the programming process as simple and easily performed without any formal robot training. If this is true why would you need a certified systems integrator? Well, many processes require unique complications such as feeding options, custom end-of-arm tools, specialty grippers, or vision inspection for defects. This is where it can get tricky, and the expertise of an experienced integrator can save you time and money.

Collaborative assembly integration can be one of the most challenging tasks when deploying your new automation. At Solara Automation we have solved some of the industry’s most difficult challenges by leaning on 15 years of automation experience. Each customer solution is different and requires different tools and approaches. We are a local North Carolina Systems Integrator with capabilities ranging from robotics integration, machine vision, automated assembly, and machine tending. We are also a Universal Robots Certified Systems Integrator and are equipped to help you design and implement your collaborative assembly solution.

Contact Solara Automation today to discuss specifically how we have solved these types of challenges.

View our custom solution videos here.